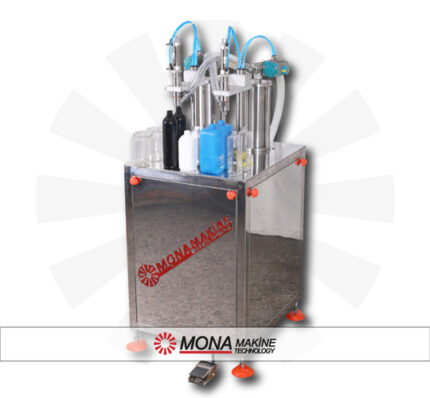

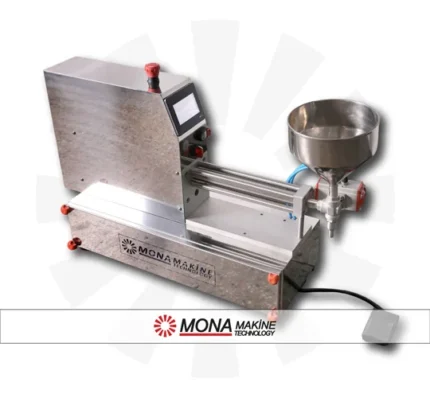

Manual Nail Polish Filling Machine is a machine with two nozzles that enables nail polish filling operations to be carried out effortlessly. The manually operated device allows effective filling of liquids the consistency of nail polish. Since it is produced from PVC plastic, it offers an innovative use. In addition, thanks to the use of INOX stainless steel, the service life of the device is long. It is known that the device, which has a wide usage area, has an ergonomic design.

What are Manual Nail Polish Filling Machines and What Do They Do?

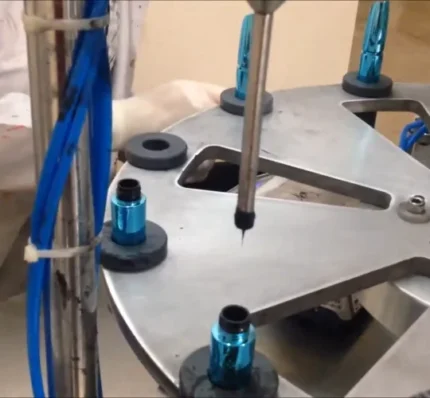

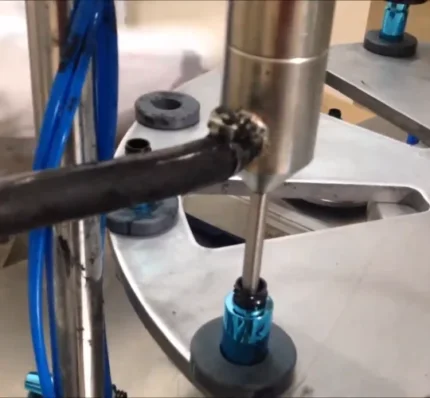

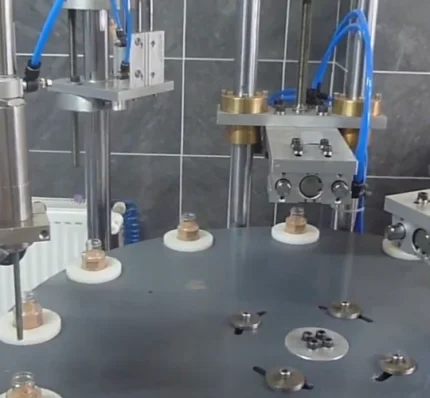

Manual Nail Polish Filling Machine, one of the devices used in nail polish filling processes, works manually. It works via a pedal or button and filling operations are done manually. It has a systematic working principle. Nail polish bottles placed under two nozzles on the machine are filled with the necessary liquid. In this way, filling operations are completed quickly and effortlessly. In addition, thanks to its features, it enables serial operation system.

What is a Manual Nail Polish Filling Machine?

Each of the devices used in nail polish filling processes has similar features. Manual Nail Polish Filling Machine differs from other devices because it has a manual working principle. Thanks to the basic operating principle of the device, nail polish bottles are placed under the nozzle. And filling operations are carried out in determined weights. Weight determination can be made at specified intervals. The device, which is frequently preferred in the cosmetics industry, also enables comfortable use thanks to its ergonomic design.

What Do Manual Nail Polish Filling Machines Do?

Manual Nail Polish Filling Machine, a technological device that allows nail polish bottles to be filled with liquid, has many advantages. All the features of the manually operated machine ensure that filling operations are completed without any problems. The device, which saves both time and cost, enables effective filling with two filling nozzles. The working principle is quite simple. Accordingly, the bottles to be filled are placed under the nozzle. Filling operations are done manually. The completed bottle is taken from the conveyor and new bottles are placed on the conveyor. In this way, the filling process is carried out quickly.