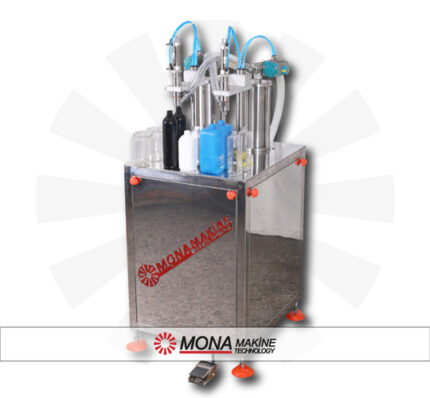

In the automatic perfume filling machine, perfume bottles enter the rotary table from the bottle feeding tray through a conveyor, and the entering perfume bottles come under the filling nozzles of the perfume filling machine and complete the filling process. Then, after completing the valve installation, valve control sensor, valve insertion, valve clamping, ring insertion, ring insertion processes, it leaves the rotary table of the perfume filling machine and moves towards the labeling machine for labeling on the same conveyor. This cycle is constantly repeated in automatic perfume filling machines.

FILLING UNIT

Empty bottles left in the bottle feeding section of the automatic perfume filling machine come under the filling nozzles. There are 3 filling nozzles in total on the machine. The filling nozzle is our own design. The nozzle fills with a vacuum pump. (As the bottle interiors are not equal, we fill the welded bottles volumetrically.) Thanks to this system, the filling is always equal. The nozzle enters the perfume bottle, which is fixed with a holder in the filling unit, and removes the air inside. The nozzle with hose connection starts filling. The other end of the hose must remain inside the chamber to absorb the perfume. This cycle continues in this way in perfume filling machines and the filling unit works in this way.

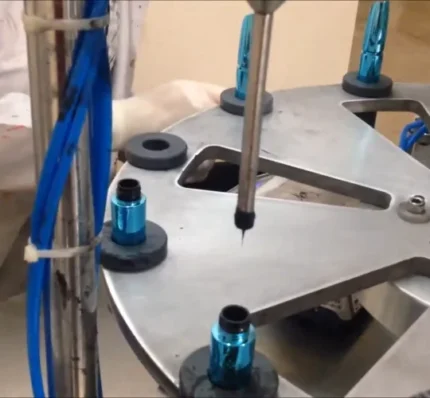

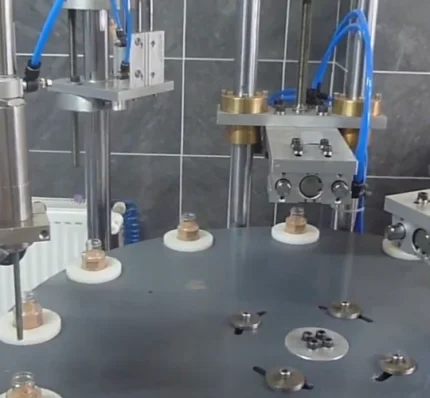

VALVE INSTALLING UNIT

The filled bottles come to the valve installation unit. Valves are cast into the bowl vibrator. Vibrator brushes find their direction by vibration. The valves it finds its direction carry to the linear vibrator. Valves coming from the linear vibrator come to the valve insertion unit. The valve insertion unit, which has the bottle underneath, puts the valve into the bottle. This cycle continues in this way in automatic perfume filling machines and the valve installation unit works in this way.

VALVE CONTROL SENSOR

The valve control unit is tasked with controlling the valves. If there is no valve in the perfume bottle, the valve notifies the setting unit with a signal. If there is no valve in the perfume bottle, the unit does not perform valve insertion. He skips the perfume bottle. This cycle continues in this way in automatic perfume machines and the valve control sensor works in this way.

VALVE FITTING UNIT

Perfume bottles with attached valves come under the valve setting unit. In this unit, it is ensured that the valve is firmly seated on the bottle. It is ensured that the valves fit properly into the bottle for the next valve clamping machine. This cycle continues in this way in automatic perfume lines and the valve pressing unit works in this way.

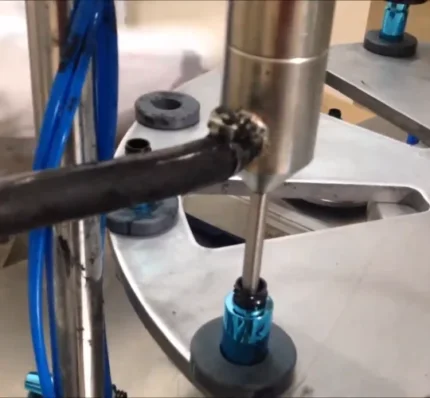

VALVE CLAMPING UNIT

Perfume bottles, whose valves are installed and hammered, come under the valve clamping unit. In this unit, the clamping process is carried out by cutting off the contact of the bottle with air through the valve. This cycle continues in this way and the valve clamping unit works in this way.

RING INSERTION UNIT

The perfume bottles, whose valves are installed and hammered, come to the ring mounting unit. The rings are poured into the bowl vibrator. Vibrator rings find their direction by vibration. The rings it finds its direction carry to the linear vibrator. The rings coming from the linear vibrator come to the ring insertion unit. The ring mounting unit, which has a bottle underneath, puts the ring on top of the bottle. This cycle continues in this way in automatic perfume filling stations and the ring attachment unit works in this way.

RING FITTING UNIT

In the last stage, the rings are fixed on the perfume bottles, by nailing them on the automatic perfume filling line. After this stage, the perfume bottles leave the rotary table and move towards the collection tray of the automatic perfume filling machine via the conveyor. This cycle continues in this way.