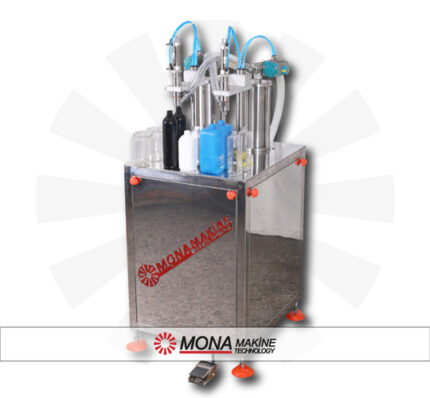

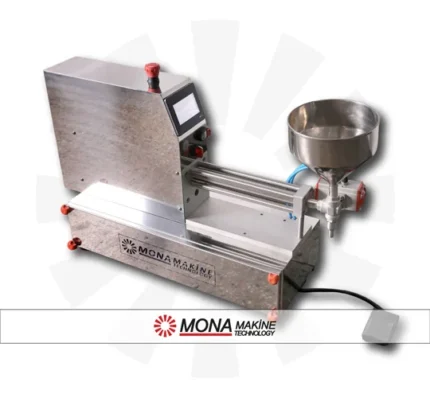

Lipgloss filling machine/Foundation filling machine/Mascara filling machine has three different units. It enables the packaging of lipgloss / mascara / foundation through these units. General features of the machine can be listed as follows:

- INOX has a stainless feature.

- Made of PVC plastic PFTE teflon.

- There is 1 filling nozzle and three different units.

It is extremely easy to mass produce lipgloss filling machines/mascara filling machines/foundation filling machines that offer high precision filling. By using a single machine in the production of foundation, lipstick and mascara, it is possible to complete the filling process and make the products ready for use.

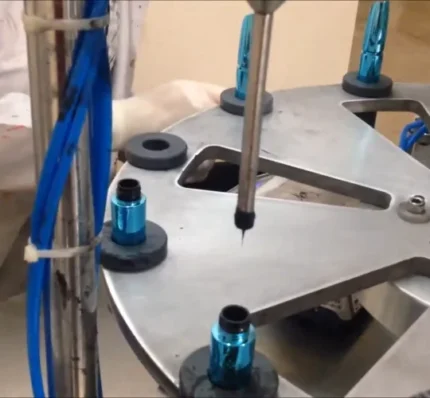

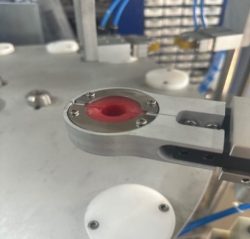

FILLING UNIT

The packages placed in the molds come under the foundation, lipgloss and mascara filling nozzle. There is 1 filling nozzle on the machine. The filling nozzle is our own design. The nozzle draws the set ml of product from the pressurized boiler and fills it into the package.

COVER FEEDING

Since this machine is a foundation filling machine, lipgloss filling machine and mascara filling machine, cap feeding is done by a personnel.

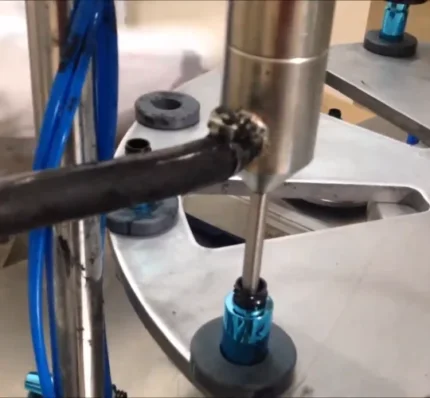

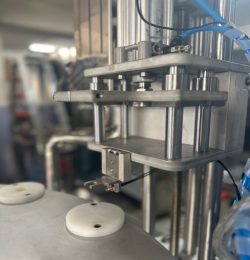

COVER TIGHTENING

The lid of the screw cap placed on the packaging filled in the molds is tightened.

PACKAGING SORTING

The lid of the package is tightened and the rotary table allows the package to be taken out of the machine with an automatic arm.

MACHINE CLEANING

The second thing to note about the machine is that the buttons on the cabin glass frame are opened and in case of manual intervention, the machine will stop for the safety of the person intervening.

Since the machine is used for foundation, mascara and lipgloss, nozzle and mold changes may occur.